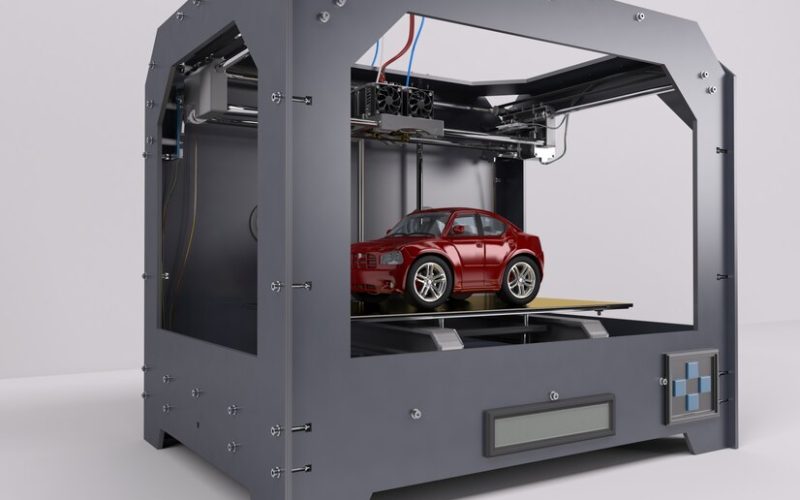

3D printing, or additive manufacturing, has undergone significant transformations since its inception in the 1980s. Initially developed for rapid prototyping, the technology has evolved into a versatile tool that finds applications across various industries, from aerospace and automotive to medical and consumer goods. Today, 3D printing encompasses multiple technologies, materials, and processes, allowing companies to innovate and optimize their production methods.

As industries increasingly adopt 3D printing, the potential applications continue to expand. This guide delves into the current state of 3D printing, exploring its transformative effects across sectors, backed by real-life examples. By the end of this guide, readers will gain a comprehensive understanding of how 3D printing drives innovation, reduces costs, and enhances product quality.

While the advantages of 3D printing are substantial, there are challenges and limitations that industries must navigate. Understanding these factors is crucial for companies considering the integration of additive manufacturing into their operations.

Material Limitations

While the range of materials available for 3D printing is expanding, it is still limited compared to traditional manufacturing methods. Many existing materials lack the mechanical properties or certifications required for specific applications, particularly in industries like aerospace and medical.

Regulatory Hurdles

In sectors such as healthcare and aerospace, stringent regulatory standards must be met. The approval process for new materials and manufacturing techniques can be lengthy and complex, posing a challenge for companies seeking to innovate quickly.

Production Speed

Although 3D printing offers rapid prototyping capabilities, the speed of producing large quantities of parts is often slower than traditional manufacturing methods like injection molding. For high-volume production, this can be a limiting factor.

Technical Expertise

Adopting 3D printing technologies requires specialized knowledge and skills. Companies may need to invest in training or hire experts to effectively integrate additive manufacturing into their existing processes.

Initial Investment Costs

The initial investment in 3D printing technology and equipment can be significant. Businesses must weigh these costs against potential long-term benefits, making the financial decision a critical factor in adoption.

The Future of 3D Printing

Despite the challenges, the future of 3D printing looks promising. As technology continues to advance, several trends are likely to shape its evolution:

Advanced Materials

Ongoing research is expected to yield new materials with enhanced properties, such as increased strength, flexibility, and temperature resistance. This expansion will broaden the scope of applications for 3D printing across various industries.

Increased Automation

The integration of automation in 3D printing processes will enhance production speed and efficiency. Companies are likely to adopt automated systems for post-processing, quality control, and monitoring, enabling a more seamless workflow.

Mass Customization

As consumer preferences shift towards personalization, 3D printing will facilitate mass customization on a larger scale. Companies will leverage additive manufacturing to create tailored products that meet individual customer needs without significant cost increases.

Sustainability Initiatives

As industries face increasing pressure to adopt sustainable practices, 3D printing’s material efficiency and ability to utilize recycled materials will play a crucial role in meeting environmental goals. Companies that embrace sustainable practices will be better positioned in a competitive marketplace.

Integration with Other Technologies

The convergence of 3D printing with other technologies such as AI, IoT, and robotics will drive innovation. These integrations will enhance design capabilities, optimize production processes, and create smarter manufacturing ecosystems.

Regulatory Evolution

As 3D printing becomes more prevalent, regulatory bodies are likely to evolve their standards to accommodate this technology. This evolution will help streamline the approval process for new materials and applications, encouraging further adoption.

The Role of 3D Printing in Aerospace

The aerospace and defense (A&D) industry was one of the earliest adopters of 3D printing, with its first applications dating back to 1989. Currently, the A&D sector accounts for approximately 16.8% of the $10.4 billion additive manufacturing market. Key players like GE, Airbus, and Boeing are heavily investing in research and development to leverage 3D printing’s unique advantages.

Benefits of 3D Printing

Low-Volume Production

In aerospace, where complex parts are often produced in low volumes, 3D printing shines. It eliminates the need for expensive tooling equipment, enabling companies to create intricate designs cost-effectively.

Weight Reduction

Weight is a critical factor in aircraft design, affecting fuel consumption and emissions. 3D printing allows for the production of lightweight parts without compromising structural integrity. For example, parts created using generative design can significantly reduce weight while maintaining strength.

Material Efficiency

Unlike traditional subtractive methods, 3D printing creates parts layer by layer, using material only where necessary. This results in minimal waste, making it a more sustainable option.

Part Consolidation

3D printing allows for the integration of multiple components into a single part, simplifying assembly and reducing the time and cost associated with manufacturing multiple pieces.

Maintenance and Repair

The lifespan of aircraft ranges from 20 to 30 years, making maintenance crucial. Technologies like Direct Energy Deposition enable the repair of critical components, such as turbine blades, by adding material to worn surfaces.

Real-Life Examples

- Ariane Group: In the manufacture of the Ariane 6 rocket, 3D printing was used to create an injector head previously composed of 248 components, reducing it to a single part. This shift decreased production time from three months to just 35 hours and halved costs.

- Airbus: The company utilizes 3D printing for producing lightweight spacer panels for the A320 aircraft. These components are 15% lighter than traditionally manufactured parts, contributing to overall fuel efficiency.

- Satair: An Airbus subsidiary, Satair leverages 3D printing to produce customized spare parts on demand. This approach minimizes inventory costs and enhances supply chain efficiency by allowing rapid response to maintenance needs.

3D Printing in the Automotive Industry

The automotive sector has increasingly adopted additive manufacturing, with revenues reaching $1.4 billion in 2019 and projected to grow to $5.8 billion by 2025. While prototyping remains a significant application, companies are exploring end-use parts and tooling as well.

Benefits of 3D Printing in Automotive

Faster Product Development

3D printing accelerates the product development cycle, allowing for rapid prototyping and testing. Designers can create multiple iterations quickly, reducing time to market.

Greater Design Flexibility

Customization

Automotive manufacturers can produce personalized parts for luxury vehicles or motorsports applications. 3D printing allows for tailored solutions that meet specific customer requirements.

Complex Geometries

3D printing is ideal for creating intricate designs, including internal channels for cooling and lightweight structures that traditional methods cannot achieve.

Real-Life Examples

- Porsche: The company has introduced 3D-printed seats for its sports cars, featuring customizable firmness levels. This innovative approach not only improves comfort but also allows for personalized designs.

- Ford: Ford has successfully utilized 3D printing for tooling aids, such as an assembly lift assist that reduced costs by 50% and improved operational efficiency. This application highlights the significant impact of additive manufacturing on production processes.

- BMW: With over one million parts 3D-printed in the past decade, BMW has demonstrated the viability of additive manufacturing for producing end-use components. The company’s metal roof bracket for the i8 Roadster weighs 44% less than its predecessor, showcasing the potential for weight reduction through 3D printing.

3D Printing in Healthcare

The medical and dental industries are among the fastest-growing sectors adopting additive manufacturing. With 97% of medical AM professionals confident in its growth, the technology is transforming patient care through personalized solutions.

Benefits of 3D Printing in Medical & Dental

Enhanced Medical Devices

3D printing allows for the rapid prototyping of medical devices, expediting the development of innovative products. Manufacturers can design and test devices quickly, reducing time to market.

Personalized Healthcare

The ability to create patient-specific devices, such as implants and prosthetics, enhances the quality of care. Custom solutions can be designed based on individual anatomy, improving fit and function.

Cost-Effective Production

3D printing reduces costs associated with traditional manufacturing methods. The ability to produce small batches of customized devices minimizes the need for large inventories and excess production.

Surgical Planning and Simulation

Surgeons can use 3D-printed models of patients’ anatomy for preoperative planning, allowing for better visualization and preparation for complex procedures.

Real-Life Examples

- Materialise: This company specializes in 3D printing for the medical sector, providing patient-specific anatomical models that assist surgeons in planning complex procedures.

- Stratasys: Stratasys has developed 3D-printed dental appliances, such as crowns and aligners, allowing for quick and accurate production tailored to individual patients.

- Prothena: The company utilizes 3D printing to produce customized prosthetics that fit the unique needs of patients, improving both comfort and functionality.

Consumer Products

3D Printing in Consumer Goods

The consumer goods sector is increasingly leveraging additive manufacturing to create personalized products, streamline production processes, and enhance design flexibility. As consumer preferences shift towards customization, 3D printing offers a viable solution.

Benefits of 3D Printing in Consumer Products

- Customization at Scale

Companies can produce unique, personalized products without the constraints of traditional manufacturing. This customization fosters a deeper connection between brands and consumers. - Rapid Prototyping

Designers can create and test multiple product iterations quickly, allowing for agile responses to market demands and trends. - Sustainability

3D printing reduces material waste and allows for the use of recycled materials, aligning with growing consumer demand for sustainable practices. - Shortened Supply Chains

Additive manufacturing can facilitate local production, reducing the need for extensive supply chains and enhancing responsiveness to consumer demands.

Real-Life Examples

- Nike: The sportswear giant has integrated 3D printing into its production processes, enabling the creation of custom footwear tailored to individual athletes’ needs.

- Adidas: Adidas employs 3D printing to produce intricate designs for its sneakers, offering unique aesthetics and performance features that appeal to consumers.

- Shapeways: As an online marketplace, Shapeways allows consumers to create and order custom 3D-printed products, from jewelry to home decor, showcasing the diverse potential of additive manufacturing in consumer goods.

Industrial Applications

3D Printing in Manufacturing

The manufacturing sector is increasingly adopting 3D printing to enhance production efficiency, reduce costs, and innovate processes. With applications ranging from tooling to end-use parts, additive manufacturing is reshaping traditional manufacturing paradigms.

Benefits of 3D Printing in Manufacturing

- Tooling and Fixtures

3D printing enables the production of custom tooling and fixtures quickly and affordably, streamlining manufacturing processes. - Shortened Lead Times

Companies can reduce lead times for parts and components, enhancing overall production efficiency. - Design Freedom

The lack of constraints associated with traditional manufacturing allows for innovative designs and complex geometries, driving product differentiation. - On-Demand Production

3D printing allows for on-demand production, reducing the need for large inventories and associated costs.

Real-Life Examples

- General Electric (GE): GE has integrated 3D printing into its manufacturing processes, producing components for gas turbines that are more efficient and lighter than traditionally manufactured parts.

- Protolabs: This company leverages 3D printing for rapid prototyping and low-volume production, allowing businesses to bring products to market faster.

- Siemens: Siemens utilizes 3D printing to produce components for its gas and steam turbines, resulting in significant

Conclusion

3D printing is revolutionizing industries by offering innovative solutions that enhance efficiency, reduce costs, and promote sustainability. As we have explored, its applications in aerospace, automotive, medical, consumer products, and industrial manufacturing demonstrate its transformative potential.

Despite the challenges, the future of 3D printing is bright, with ongoing advancements in materials, automation, and integration with other technologies paving the way for broader adoption. Companies that embrace this technology will likely gain a competitive edge, enabling them to innovate and respond swiftly to changing market demands.

As we continue to explore the possibilities of additive manufacturing, it’s clear that 3D printing will play a pivotal role in shaping the future of production, driving advancements across multiple sectors. Embracing this technology is not just a trend but a strategic move toward a more efficient, customized, and sustainable industrial landscape.