The impact of 3D printing on the manufacturing industry is profound, revolutionizing production processes, customization capabilities, and supply chain efficiencies. This article explores how 3D printing technology is reshaping manufacturing across various sectors.

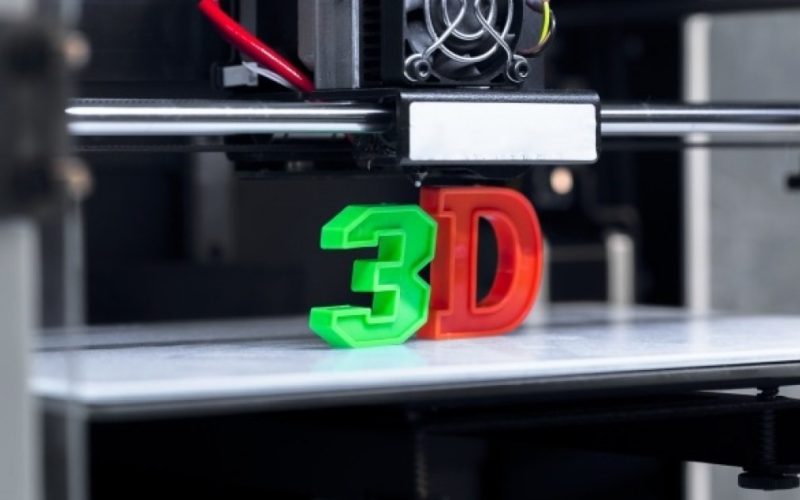

1. Introduction to the Impact of 3D Printing

3D printing, also known as additive manufacturing, builds three-dimensional objects layer by layer from digital designs. Its versatility and flexibility are transforming traditional manufacturing methods, offering new possibilities in product design and production.

2. Accelerated Prototyping and Design Iterations

One of the significant advantages of 3D printing is rapid prototyping. Manufacturers can quickly create prototypes and iterate designs based on real-world testing and feedback. This agility reduces time-to-market and enhances product development cycles.

3. Customization and Personalization in Manufacturing

Impact of 3D printing extends to customization, allowing for personalized products tailored to individual customer preferences. Mass customization is feasible without incurring high costs or compromising production efficiency, catering to niche markets and consumer demands.

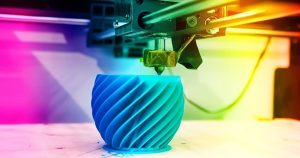

4. Complex Geometries and Design Freedom

Traditional manufacturing methods often have limitations in producing complex geometries. 3D printing enables the fabrication of intricate designs, including lattice structures and organic shapes, which are challenging or impossible to achieve with conventional techniques.

5. Supply Chain Optimization and Localized Production

3D printing reduces reliance on centralized manufacturing hubs by enabling localized production. This decentralization optimizes supply chains, reduces transportation costs, and minimizes inventory overheads by producing goods closer to the point of consumption.

6. Sustainability and Material Efficiency

Impact of 3D printing includes sustainability benefits through reduced material waste. Additive manufacturing processes utilize materials more efficiently by only using what is necessary for production, contributing to environmental conservation and resource efficiency.

7. Tooling and Spare Parts Manufacturing

3D printing technology is instrumental in producing custom tooling, jigs, and fixtures quickly and cost-effectively. It also facilitates on-demand production of spare parts, reducing downtime and inventory storage costs for maintenance and repair operations.

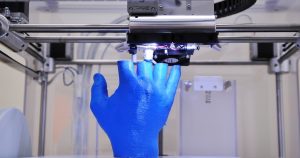

8. Adoption Across Industries

Various industries, from aerospace and automotive to healthcare and consumer goods, embrace the impact of 3D printing. Each sector leverages additive manufacturing for unique applications, such as lightweight components, medical implants, and architectural models.

9. Technological Advancements and Future Trends

Ongoing advancements in 3D printing technology include faster printing speeds, larger build volumes, and improved material options. Future trends foresee integration with AI for automated design optimization and bioprinting for medical and biological applications.

10. Challenges and Considerations

Despite its benefits, impact of 3D printing faces challenges like scalability for mass production, quality control standards, and intellectual property protection. Addressing these considerations requires continued innovation, regulatory frameworks, and industry collaboration.